Products

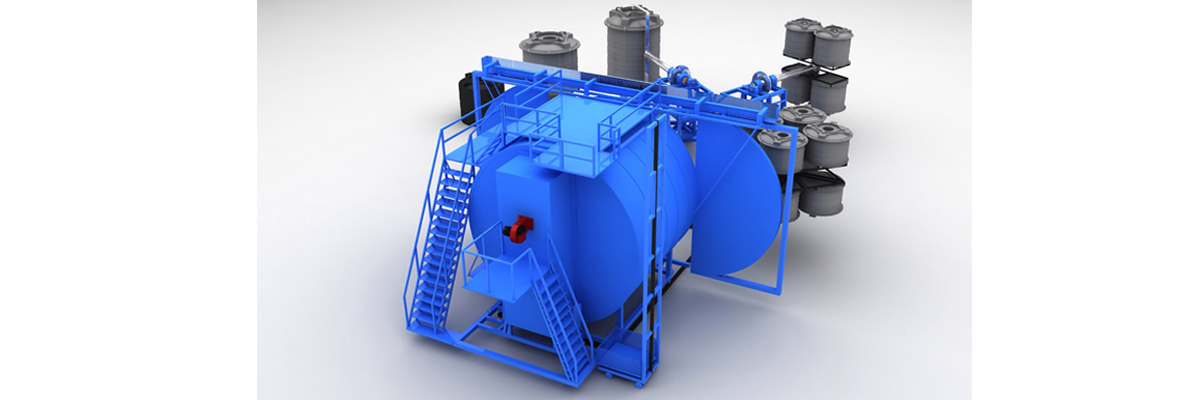

| MODEL | SM-4A -400 FOUR ARM BIAXIAL |

| Machine Type | Movable Round oven 4 arm biaxial machine.(Straight Arm–3 Nos + 1 offset ar |

| Oven size | 4000 mm Dia X 3000 mm Depth |

| Heating oven | Double skin 14 SWG CRC SHEET having 150 MM thickness with Insulation material (cerawool pad) in between two layers. With inspection window & Second charge system on top of the oven to reduce cycle time & heat loss. Worldwide accepted design for best fuel efficiency. |

| Oven Door | Heating chamber door having 150 MM thickness Operated threw control panel heaving gear motor / rack n pinion drive both door run by Motor 1 HP X 2 nos. with variable drive with pneumatic door locking system. (Compressor with 500ltrs air receiver / not in scope of supply.) |

| Heat source | Gas /Diesel |

| Burner | Self Ignitions Riello make (MADE IN ITALY ) |

| Heat Recirculation blower | Fully insulated heating chamber with 2 no. belt driven blower 5 HP stranded make A.C motor ( blower heaving 15000 CFM.) |

| Oven travel | Operated threw control panel heaving 2 hp motor with variable drive with interlocking system ( oven travel only when door is open ) |

| Step stand / lift/ second charge (with extra price) |

1 no. 0.2 hp motor ( power pack ) hydraulic lift to facilitate upward movement To transfer material to oven top .also fabricated staircase to be provided |

| Station | Covered by mild steel sheet 16 swg cover main station from heavy mild steel structure. Heavy duty ARM stands from square tube (graded) material. One pillar of sleep ring for each arm separator wire connection from motor to main control panel station rotate by 0.1 hp X 2 nos. gear motor with variable drive coupled to station wheel threw helical gear |

| Sleepring | Ring & carbon brush holder made from brass material easy to wiring and trouble free working. |

| Cooling fan | 1 HP x 6nos. high efficiency industrial cooling fan. |

| Straight arm specification | Straight arm 03 nos. |

| Minor axis speed : - 1 - 06 RPM (settable with variable drive ) | |

| Major axis speed :- 1 – 11 RPM (settable with variable drive ) | |

| Gear & motor : - connected by helical gears | |

| Drive ( A.C motor ) 05 hp for major (1440 RPM ) | |

| Drive ( A.C motor ) 02 hp for minor (1440 RPM ) | |

| Offset arm specification | Offset arm 1 no. |

| Minor axis speed : - 1 - 06 RPM (settable with variable drive ) | |

| Major axis speed :- 1 – 11 RPM (settable with variable drive ) | |

| Gear & motor : - connected by helical gears | |

| Drive ( A.C motor ) 7.5 hp for major (1440 RPM) | |

| Drive ( A.C motor ) 02 hp for minor (1440 RPM) | |

| Total power | 65 HP ( 3 PHASE 440 V/ 50Hz)APPROX. |

| Motor | ABB MAKE |

| Gear boxes | STANDRED MAKE |

| Control | Design of control panel is to serve user friendly functional requirement & safety and manufactured with switch gear from world leader Schneider electric |

| Control functions | |

| · Independent moveable control desk ( separate from panel ) | |

| · AC variable speed control of major & minor axis of arms | |

| · For / rev direction of major & minor settable independently. | |

| · Oven temperature maintained automatically at set value. | |

| · Auto positioning of turret with Manuel reverser button | |

| MONITORING functions | |

| Oven temperature, motor load in AMP. Of all major / minor axis monitored | |

| For / rev & stop time of major or minor axis & burner on | |

| Audio alarm for heating time completion & faults | |

| Safety function | |

| Necessary inter locks between oven travel , doors & turret with limit switches | |

| All AC drives include provide with precaution like over / under voltage, motor over load, single phasing, earth leakage & AC drives fault indication. |

|

| All motors are protected with individual MCBS & OVER LOAD REALYS | |

| Audio alarms for before main control on , movement like oven travel , door | |

| Emergency stop button |

| Model Number | Production(24 Hr) | Arms | Arm Type | Swing Diameter | Heating Fuel | Cooling System | Connected Load | Space Required | Burner | Supply Voltage |

| SM-2A-150 | 20,000 Liters | 2 | 1-Straight/1-Offset | 1500 mm | Gas/Diesel | Air & Water | 12 Hp | 6000*3000*2500 | Single Stage | 415 Volt 50 Hz |

| SM-2A-150 | 25,000 Liters | 2 | 1-Straight/1-Offset | 2100 mm | Gas/Diesel | Air & Water | 15 Hp | 8000*5000*3000 | Single Stage | 415 Volt 50 Hz |

| SM-2A-150 | 30,000 Liters | 2 | 1-Straight/1-Offset | 2500 mm | Gas/Diesel | Air & Water | 17 Hp | Single Stage | 415 Volt 50 Hz | |

| SM-2A-150 | 40,000 Liters | 2 | 1-Straight/1-Offset | 2800 mm | Gas/Diesel | Air & Water | 17 Hp | Single Stage | 415 Volt 50 Hz | |

| SM-3A-150 | 25,000 Liters | 3 | 2-Straight/1-Offset | 1500 mm | Gas/Diesel | Air & Water | 15 Hp | 8000*5000*3000 | Single Stage | 415 Volt 50 Hz |

| SM-3A-210 | 30,000 Liters | 3 | 2-Straight/1-Offset | 2100 mm | Gas/Diesel | Air & Water | 20 Hp | 10000*7000*3500 | Single Stage | 415 Volt 50 Hz |

| SM-3A-280 | 45,000 Liters | 3 | 2-Straight/1-Offset | 2800 mm | Gas/Diesel | Air & Water | 20 Hp | 12000*10000*4000 | Single Stage | 415 Volt 50 Hz |

| SM-3A-320 | 75,000 Liters | 3 | 2-Straight/1-Offset | 3200 mm | Gas/Diesel | Air & Water | 27 Hp | 12000*11000*5000 | Single Stage | 415 Volt 50 Hz |

| SM-3A-350 | 85,000 Liters | 3 | 2-Straight/1-Offset | 3500 mm | Gas/Diesel | Air & Water | 30 Hp | 12000*11000*5000 | Single Stage | 415 Volt 50 Hz |

| SM-3A-350 | 80,000 Liters | 3 | 3-Straight | 3800 mm | Gas/Diesel | Air & Water | 25 Hp | 12000*11000*5000 | Single Stage | 415 Volt 50 Hz |

| SM-4A-350 | 100,000 Liters | 4 | 2-Straight/2-Offset | 3500 mm | Gas/Diesel | Air & Water | 43 Hp | 15000*13000*5000 | Single Stage | 415 Volt 50 Hz |

| SM-4A-400 | 150,000 Liters | 4 | 2-Straight/2-Offset | 4000 mm | Gas/Diesel | Air & Water | 60 Hp | 18000*15000*6000 | Single Stage | 415 Volt 50 Hz |

| SM-4A-450 | 180,000 Liters | 4 | 2-Straight/2-Offset | 4500 mm | Gas/Diesel | Air & Water | 70 Hp | 18000*15000*6000 | Single Stage | 415 Volt 50 Hz |

| SM-4A-500 | 200,000 Liters | 4 | 2-Straight/2-Offset | 5000 mm | Gas/Diesel | Air & Water | 80 Hp | 18000*15000*6000 | Single Stage | 415 Volt 50 Hz |

| SM-4A-550 | 250,000 Liters | 4 | 2-Straight/2-Offset | 5500 mm | Gas/Diesel | Air & Water | 100 Hp | 12000*11000*5000 | Single Stage | 415 Volt 50 Hz |

Get A Free Quote / Need a Help ?

Contact Us